Running News Daily

Running News Daily is edited by Bob Anderson. Send your news items to bob@mybestruns.com Advertising opportunities available. Train the Kenyan Way at KATA Kenya and Portugal owned and operated by Bob Anderson. Be sure to catch our movie A Long Run the movie KATA Running Camps and KATA Potato Farms - 31 now open in Kenya! https://kata.ke/

Index to Daily Posts · Sign Up For Updates · Run The World Feed

Can Robots Really Replace Human Hands in Making Running Shoes?

Some people think the answer to making running shoes in the United States is simple: just use robots. Let’s explore this concept, says lifelong runner and publisher Bob Anderson, who recently sparked a lively conversation online after posting, “It’s just not realistic to imagine an American company finding enough labor in the U.S. to make running shoes.”

Anderson’s concern is shared by many runners who are watching shoe prices soar. “At this rate,” he added, “running shoes could cost $400 or more unless companies sacrifice their markup—which could cause other problems.”

So, could robotics be the solution?

“It’s never too late,” one reader commented on Facebook. “Eventually shoes will be manufactured using robotics. Imagine how inexpensive shoes will be then.”

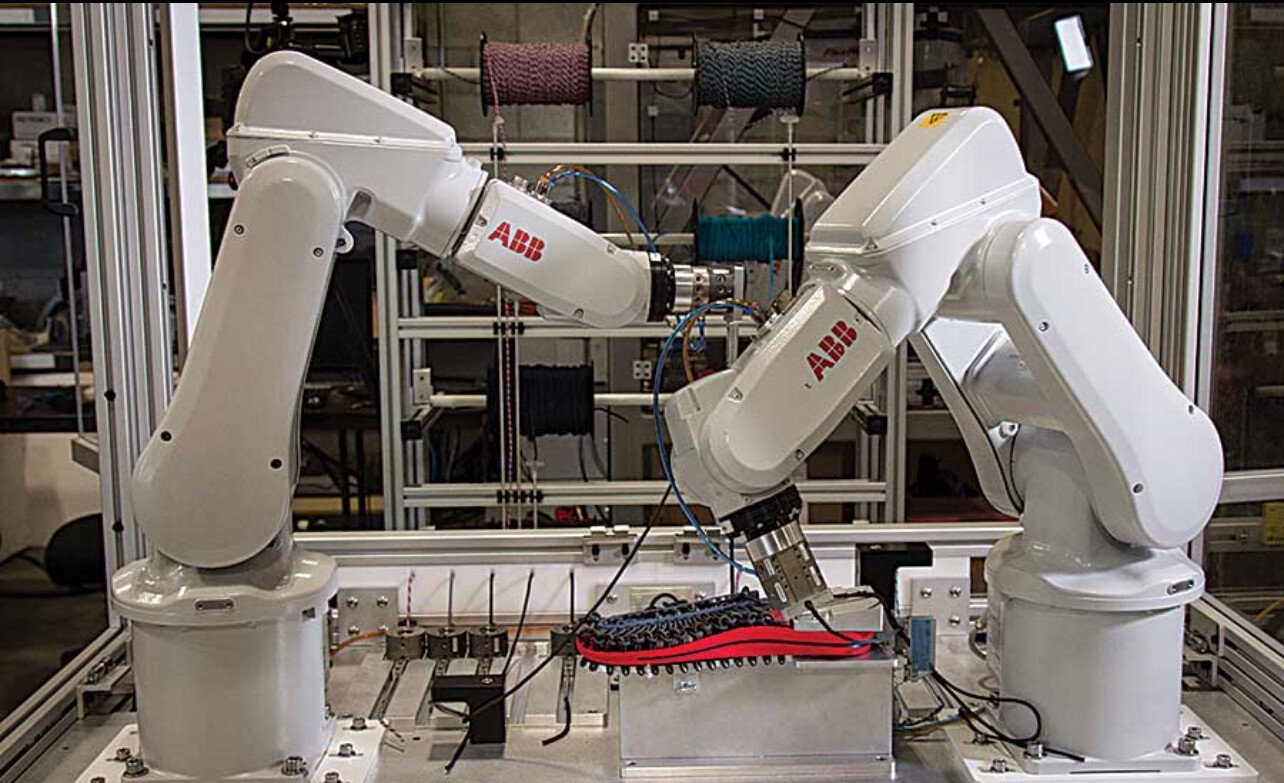

It’s a logical idea. Automation has changed industries from cars to electronics. But as Anderson and others pointed out in the thread, running shoes are a unique challenge. The materials are flexible, the stitching is complex, and every design has slight variations. Even with advances in AI and robotics, there’s still no fully automated way to produce a quality performance shoe from start to finish.

Lan Rupf responded: “Years ago, Steve Jobs wanted to manufacture in Fremont using automation. It couldn’t be done. Same for Elon’s wish. It’s just too expensive and too complex.” Last photo Bob's current shoes.

Let’s talk numbers. A full robotic setup capable of handling key parts of shoe production can cost upwards of $500,000–$750,000 when you factor in software, installation, and maintenance. If each pair of shoes saves $2.50 in labor costs compared to overseas production, a company would need to manufacture 300,000 pairs over five years just to break even. That’s 60,000 pairs per year—and that’s assuming full uptime, perfect output, and no production issues.

In contrast, factories in Vietnam, Indonesia, and China can produce millions of pairs annually, using skilled human labor that costs under $2 an hour. These workers are often happy to have the job, and the factories are already optimized for efficiency.

Another reader brought up ON Running’s use of robotics to custom-fit shoes, saying “Robotics will be doing many of these jobs.” True—there are steps toward automation happening. But these are limited use-cases, and even ON still relies heavily on human workers in final assembly.

And beyond feasibility, there’s the bigger question: Even if we could automate everything, should we?Rupf warned, “If every job can be done by robots 100%, the majority of people in this world will be out of jobs. The future will be very bleak.”

So what’s the takeaway?

Right now, it’s too late to bring back large-scale running shoe factories to the U.S. using traditional labor, and it’s still too soon for robotics to be the magic solution. The most likely future? A hybrid approach, with robots assisting in certain areas, while skilled human workers overseas continue to handle the core of the work.

But for now, as Anderson concludes, “Don’t expect your next pair of running shoes to be made by a robot—in the U.S. or anywhere else.”

by Boris Baron

Login to leave a comment

The last photo is my closet. I always have several pairs to pick from. - Bob Anderson 5/2 4:04 pm |